100% Original Auto Edge Banding Machine - Edge Banding Woodworking Machine – Tenglong Machinery

100% Original Auto Edge Banding Machine - Edge Banding Woodworking Machine – Tenglong Machinery Detail:

1. Feeding group: Put the card into the cassette, and pull the card down to the transport arm by the pulling cylinder using the vacuum suction cup.

2. Material rack group: Put the chip hot melt tape into the material rack correspondingly, and then introduce the chip hot melt adhesive through the guide wheel into the rubber punching paper mold, pre-soldering group, punching chip group, etc., Lead the belt into the corresponding position and put it away.

3. Pre-welding group: heating element heating, temperature sensor and temperature controller cooperate to control the heating temperature, the time is set by the touch screen, the pot welding head performs hot melt glue and module backing under the action of the cylinder, according to different modules, change Use the corresponding pot welding head, such as eight contacts and six contacts.

4. Module quality identification group: the identification hole of the bad module is sensed by the reflective electric eye, and the signal is sent to the PLC. After the signal, the PLC will transmit the bad module signal to the die punching group, and the die will not punch some modules. The card corresponding to the module is not spot welded and heat welded, and the card is sent to the waste box when the IC inspection group is packaged.

Factory scene

In the process of development, the company has continuously communicated and cooperated with many domestic scientific research institutions, and its design and production, maintenance and debugging and engineering transformation capabilities have been rapidly improved, and the scale has continued to expand.

Pursuing the policy of “enterprising, truth-seeking, rigorous and unity”, constantly pioneering and innovating, with technology as the core, quality as life, and customers as God, we will wholeheartedly provide you with the most cost-effective automatic control products, high-quality engineering design and transformation, and meticulous after-sales service .

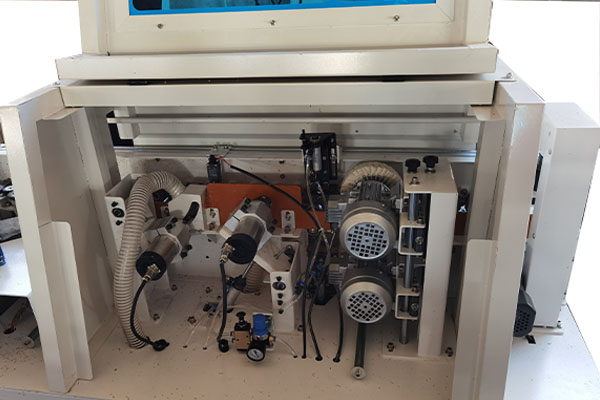

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for 100% Original Auto Edge Banding Machine - Edge Banding Woodworking Machine – Tenglong Machinery , The product will supply to all over the world, such as: Sri Lanka, Montpellier, Romania, We'd like to invite customers from abroad to discuss business with us. We can present our clients with high quality products and excellent service. We're sure that we'll have good cooperative relationships and make a brilliant future for both parties.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.