2021 High quality Circular Saw Machine For Wood Cutting - Automatic horizontal band saw for machine tool woodworking work – Tenglong Machinery

2021 High quality Circular Saw Machine For Wood Cutting - Automatic horizontal band saw for machine tool woodworking work – Tenglong Machinery Detail:

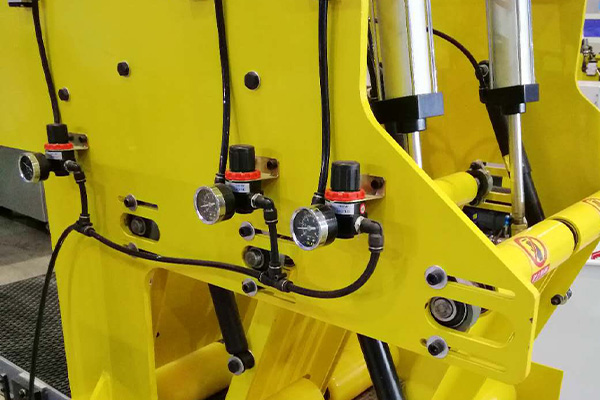

Horizontal woodworking band saw machine is composed of saw frame, parallelogram adjustment device or four screw adjustment device, grinding saw machine, rail and lifting bracket. A tool for removing the veneer from the bottom of the log. When the machine is working, the wood is fixed and the track is fixed on the wood. The sawing machine is installed on the track, and the thickness of the processed wood is adjusted through the parallelogram adjusting device, so that the sawing machine cuts along the plane of the wood.

Horizontal band saws can be specialized in the production and processing of mahogany furniture, pine, etc., saving labor, materials, and environmental protection during processing. It is the first choice for all wood processing factories and furniture factories.

Advantage

1.Built to the exacting standards demanded by today’s professionals, features state. of-the, art systems such as digital controls,precision blade tensioning with gauge, and a variable. speed conveyor drive system.

2.Automatic tensioning: The Rexroh rails are ftted with a tensioning system to make the saw blade more durable.

3.The sawing wheel has advanced processing technology, good stability, wear resistance, and the saw blade is not easy to break. UsesJapan imported NSK6200VV and NSK32013

bearing to ensure smooth rotation of the saw wheel.Zhengtai,SIMENS, LG and other imported electrical components: the electrical box is durable and not easy to damage.

4.A strong power,3-phase motor rounds out this machine for unsurpassed power to handle your biggest resaw operations.

5.Wear-resistant ceramic saw clamp to protect the saw blade for efficient heat dissipation and better sawing surface quality

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand abroad business" is our progress strategy for 2021 High quality Circular Saw Machine For Wood Cutting - Automatic horizontal band saw for machine tool woodworking work – Tenglong Machinery , The product will supply to all over the world, such as: Honduras, Hanover, Sri Lanka, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!