Featured

-

2021 Latest Design Sell My Woodworking Machinery – Desktop woodworking automatic spiral planer – Tenglong Machinery

The high-speed precision spiral planer is a new product developed by Weishi Precision Machinery. It fully solves the problems of processing wood boards. The worktable is automatically raised and lowered, and the conveyor belt is stepless speed regulation. It fully meets the working conditions of various processing ranges and speeds. It is simple to operate. The machining accuracy is stable in size, and the efficiency is 3-6 times higher than that of ordinary press planing. The maximum conveyi... -

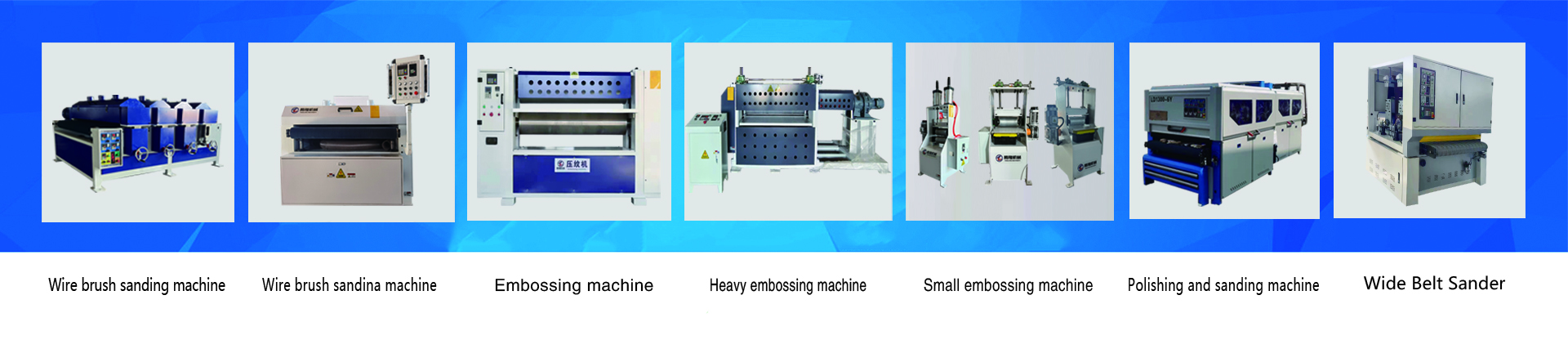

Wholesale Price Embossing Machine For Sale - Multi-specification custom embossing machine 650mm – Tenglong Machinery

Embossing machine is widely used in solid wood door panels, cabinet panels, furniture panels and other surfaces to extrude simulated wood grain, with strong three-dimensional effect. The solid wood furniture made is high-end and generous, with strong visual effects. It is the best surface treatment method for a new generation of solid wood furniture. . The pattern is made by imported 5-axis linkage CNC laser engraving machine to ensure quality, workmanship, and fine carving! The pattern is ad... -

100% Original Wood Work Equipment - Desktop woodworking special furniture manufacturing drilling machine – Tenglong Machinery

The boring machine is a machine tool that mainly uses a boring tool to boring the existing pre-made holes of the workpiece. Generally, the rotation of the boring tool is the main motion, and the movement of the boring tool or the workpiece is the feed motion. It is mainly used to process high-precision holes or finish machining of multiple holes at a time. In addition, it can also be engaged in the processing of other machining surfaces related to hole finishing. Different tools and accessori... -

Wholesale Price Moulder Machine - Desktop woodworking automatic spiral planer – Tenglong Machinery

The high-speed precision spiral planer is a new product developed by Weishi Precision Machinery. It fully solves the problems of processing wood boards. The worktable is automatically raised and lowered, and the conveyor belt is stepless speed regulation. It fully meets the working conditions of various processing ranges and speeds. It is simple to operate. The machining accuracy is stable in size, and the efficiency is 3-6 times higher than that of ordinary press planing. The maximum conveyi... -

Hot New Products Ide Belt Sander - Desktop woodworking automatic spiral planer – Tenglong Machinery

The high-speed precision spiral planer is a new product developed by Weishi Precision Machinery. It fully solves the problems of processing wood boards. The worktable is automatically raised and lowered, and the conveyor belt is stepless speed regulation. It fully meets the working conditions of various processing ranges and speeds. It is simple to operate. The machining accuracy is stable in size, and the efficiency is 3-6 times higher than that of ordinary press planing. The maximum conveyi... -

Hot sale Wood Saw Cutter - Automatic horizontal band saw for machine tool woodworking work – Tenglong Machinery

Horizontal woodworking band saw machine is composed of saw frame, parallelogram adjustment device or four screw adjustment device, grinding saw machine, rail and lifting bracket. A tool for removing the veneer from the bottom of the log. When the machine is working, the wood is fixed and the track is fixed on the wood. The sawing machine is installed on the track, and the thickness of the processed wood is adjusted through the parallelogram adjusting device, so that the sawing machine cuts al... -

2021 Good Quality Sander Machine For Wood - Desktop woodworking special furniture manufacturing drilling machine – Tenglong Machinery

The boring machine is a machine tool that mainly uses a boring tool to boring the existing pre-made holes of the workpiece. Generally, the rotation of the boring tool is the main motion, and the movement of the boring tool or the workpiece is the feed motion. It is mainly used to process high-precision holes or finish machining of multiple holes at a time. In addition, it can also be engaged in the processing of other machining surfaces related to hole finishing. Different tools and accessori... -

Factory Supply Multi Drilling Machine Price - Desktop woodworking special furniture manufacturing drilling machine – Tenglong Machinery

The boring machine is a machine tool that mainly uses a boring tool to boring the existing pre-made holes of the workpiece. Generally, the rotation of the boring tool is the main motion, and the movement of the boring tool or the workpiece is the feed motion. It is mainly used to process high-precision holes or finish machining of multiple holes at a time. In addition, it can also be engaged in the processing of other machining surfaces related to hole finishing. Different tools and accessori... -

Factory directly Gumtree Woodworking Machinery - Desktop woodworking automatic spiral planer – Tenglong Machinery

The high-speed precision spiral planer is a new product developed by Weishi Precision Machinery. It fully solves the problems of processing wood boards. The worktable is automatically raised and lowered, and the conveyor belt is stepless speed regulation. It fully meets the working conditions of various processing ranges and speeds. It is simple to operate. The machining accuracy is stable in size, and the efficiency is 3-6 times higher than that of ordinary press planing. The maximum conveyi... -

OEM/ODM Manufacturer Marunaka Woodworking Machinery - Desktop woodworking automatic spiral planer – Tenglong Machinery

The high-speed precision spiral planer is a new product developed by Weishi Precision Machinery. It fully solves the problems of processing wood boards. The worktable is automatically raised and lowered, and the conveyor belt is stepless speed regulation. It fully meets the working conditions of various processing ranges and speeds. It is simple to operate. The machining accuracy is stable in size, and the efficiency is 3-6 times higher than that of ordinary press planing. The maximum conveyi... -

Factory Outlets Cutter Head For Spindle Moulder - Desktop woodworking automatic spiral planer – Tenglong Machinery

The high-speed precision spiral planer is a new product developed by Weishi Precision Machinery. It fully solves the problems of processing wood boards. The worktable is automatically raised and lowered, and the conveyor belt is stepless speed regulation. It fully meets the working conditions of various processing ranges and speeds. It is simple to operate. The machining accuracy is stable in size, and the efficiency is 3-6 times higher than that of ordinary press planing. The maximum conveyi... -

OEM Factory for Spindle Moulder With Sliding Table - Desktop woodworking automatic spiral planer – Tenglong Machinery

The high-speed precision spiral planer is a new product developed by Weishi Precision Machinery. It fully solves the problems of processing wood boards. The worktable is automatically raised and lowered, and the conveyor belt is stepless speed regulation. It fully meets the working conditions of various processing ranges and speeds. It is simple to operate. The machining accuracy is stable in size, and the efficiency is 3-6 times higher than that of ordinary press planing. The maximum conveyi...