Professional China Curved-Surface Brush Sanding Machine - Polishing Sander Machine for Wooden – Tenglong Machinery

Professional China Curved-Surface Brush Sanding Machine - Polishing Sander Machine for Wooden – Tenglong Machinery Detail:

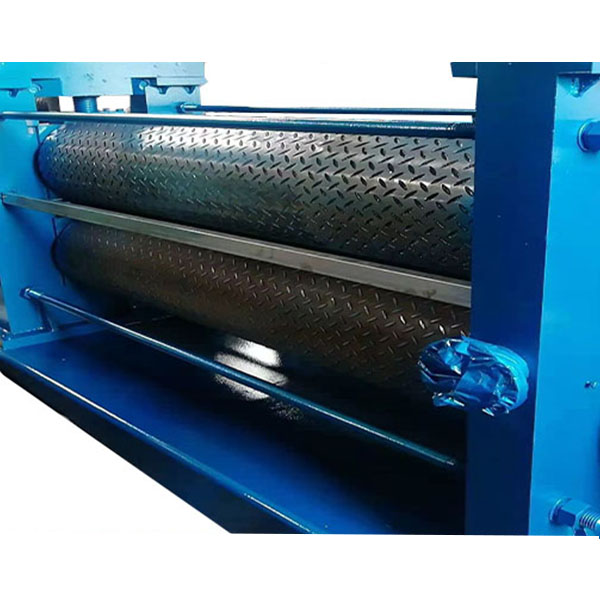

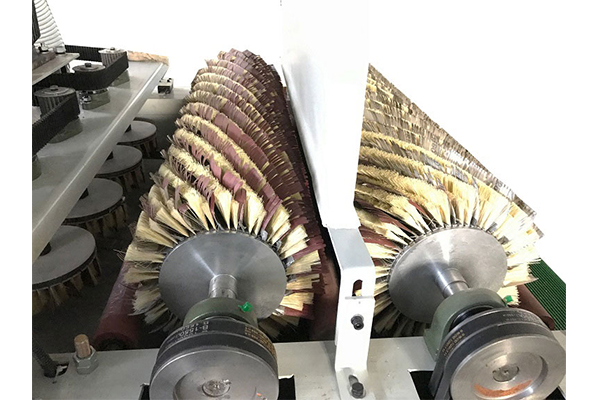

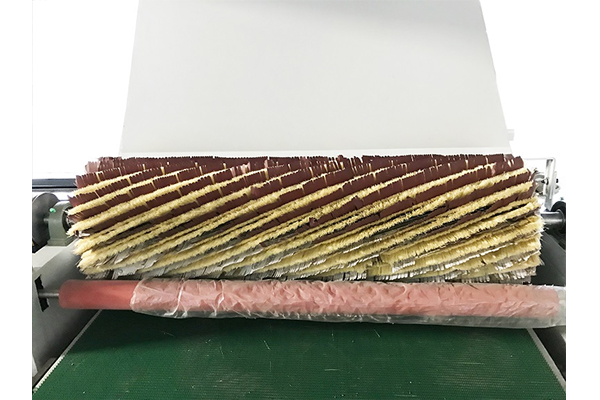

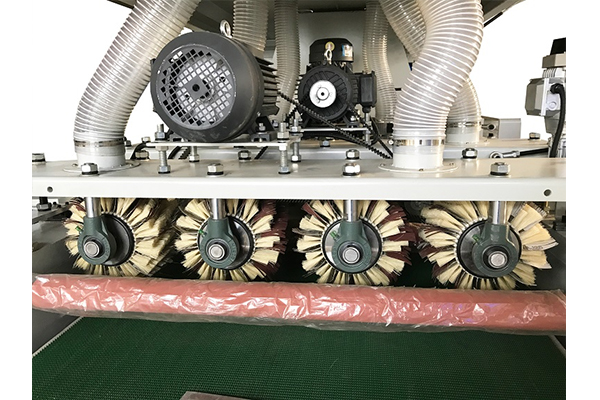

The special-shaped sanding machine is composed of a sisal grinding wheel and a grinding wheel, one roller, one machine with two rollers, two-way forward and reverse grinding. It adopts multi-gradient grinding wheel tooth profile, combined with electric lifting to control the height of the roller group, for effective grinding of sheet surface milling or engraving simple grooves, etc., easy to operate, the combination of the two can grind complex and special-shaped flat plates at one time, with better results.

Sander is a commonly used processing equipment for woodworking. As the name suggests, the name sander refers to the sanding treatment of wood surfaces. However, the role of modern wide-band sanding machine is not only to sand the surface of wood, it has many functions.

1. Fixed thickness sanding to improve the thickness accuracy of the workpiece, such as the veneer base material, which is used when the fixed thickness sanding is required before the veneer.

2. Surface sanding refers to the process of improving the surface quality and removing a layer of sand evenly on the surface of the board to eliminate the knife marks left by the previous process and make the surface of the board beautiful and smooth.

Clean, also used for veneer, dyeing, printing, painting.

3. Sand wool refers to the sanding process to improve the roughness of the back of the decorative board in order to ensure the bonding strength between the veneer of the decorative board and the base material.

Products Show

This machine is suitable for the polishing of solid wood furniture, wooden doors, density boards, mahogany, carved plates, etc.

Optional rules 1000, 1300 (four-axis, six-axis, eight-axis)

Regardless of whether it is a regular surface or a special-shaped surface and curved surface, rough and fine polishing can be carried out, and the sanding and polishing effect of the wood surface is remarkable.

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for Professional China Curved-Surface Brush Sanding Machine - Polishing Sander Machine for Wooden – Tenglong Machinery , The product will supply to all over the world, such as: Washington, Venezuela, Jersey, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!