One meter three 8-channel special-shaped sanding machine

Basic Info.

| model | One meter three eight | After-sales service | online |

| colour | Iron gray | trademark | Tenglong |

| Application field | Cabinet door/wooden door | custom made | custom made |

| Transport package | wood | Warranty | 1 year |

| origin | China | Automatic level | automatic |

Product Description

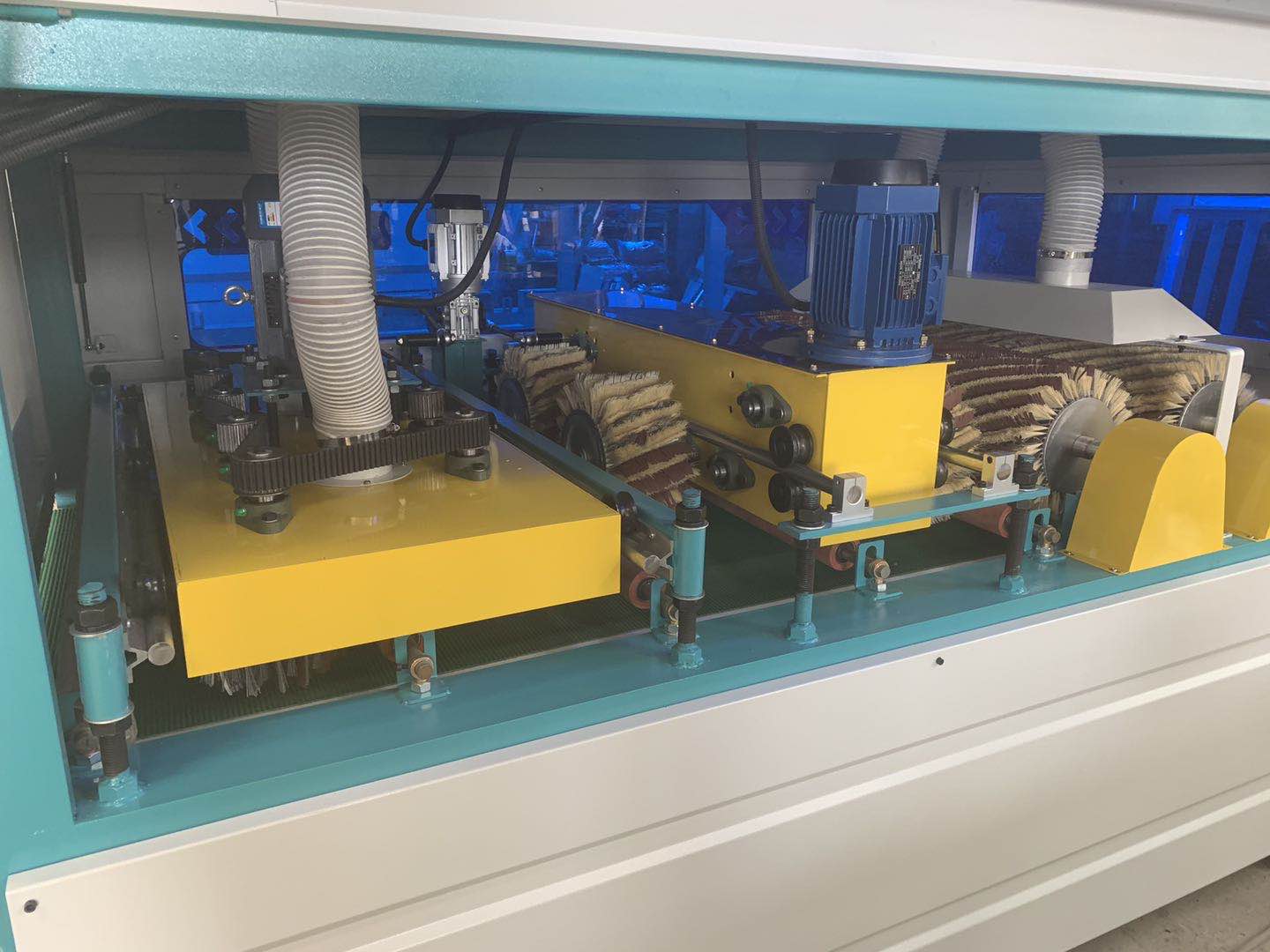

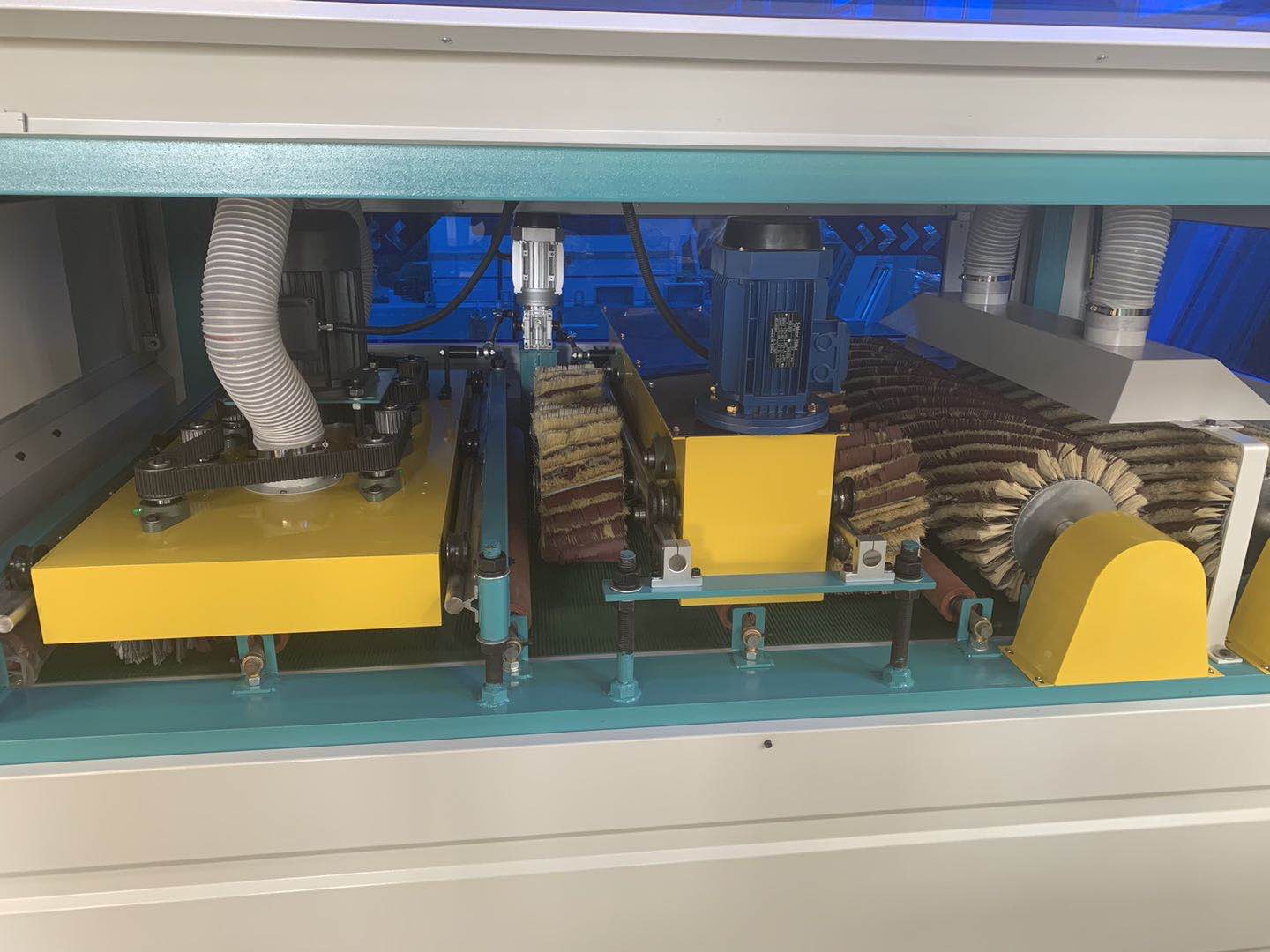

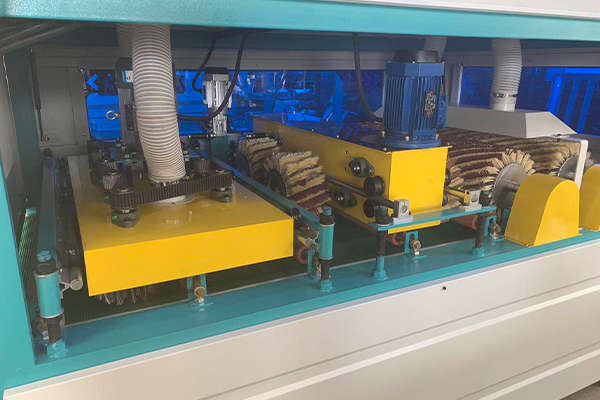

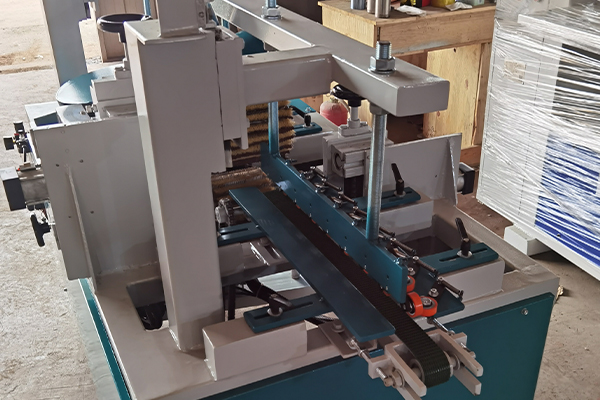

The main structure of the machine is a combination of abrasive belts and different types of deburring and grinding brushes. Each station can be used independently or in combination: above, it is suitable for various products and various processes required by the factory. Through processing, instead of effective manual polishing work. Using the stable and reliable patented belt control technology, the deburring and chamfering can be completed at one time. The operation is portable and intuitive. The equipment has a built-in LED light source. The vacuum conveying platform can be processed to find jobs. The grinding is flexible and does not damage the surface of the workpiece. Optional wet dust collector can be used to vacuum when working.

Product Parameters

1. Rotating control panel: It is very easy to control the machine. The speed of the six rollers is controlled by three frequency converters, and the speed of the rollers is easily controlled by the switch on the control panel. Workers can adjust the speed according to different materials.

2. Cross rollers: Two sets of cross rollers (9 in total) rotate independently and move forward at the same time to ensure the grinding effect of the surface and the transverse grooves.

3. Disc brushes: Two groups of disc brushes (9 disc brushes in total) rotate in the opposite direction, and the roller speed is frequency-converted. This machine can realize the unevenness and edge grinding of different angles through the movement of the plate itself and the rotation of the disc brush.

4. Longitudinal rollers: The two sets of long brush rollers rotate in opposite directions, which can be raised and lowered independently to ensure the omnidirectional rough surface and R angle polishing effect.

5. It is suitable for the shaping and fine grinding of laminated materials, composite boards, particle boards, solid wood, panel furniture, bamboo floors, wooden doors, etc. It is one of the necessary equipment for laminated materials. And furniture manufacturing.

6. R-RP type: the first roller is a steel roller; the second unit is an 85 ° rubber roller with an air sand pad. RP-P type: The first unit is a rubber roller with sand pad; the second unit is an air sanding pad.

Steel rollers are used for aligning and polishing, and rubber rollers are used for fine polishing.

7. The pressure roller protection device keeps the plate on the feeding table to ensure the safety of the operator.

Detailed Photos