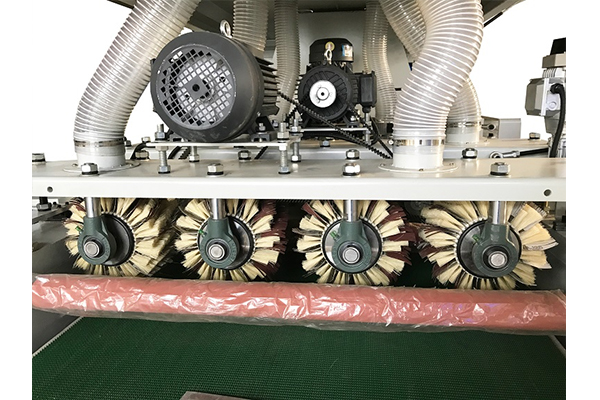

Brush Sander Machine,Used for polishing solid wood furniture

Product Description

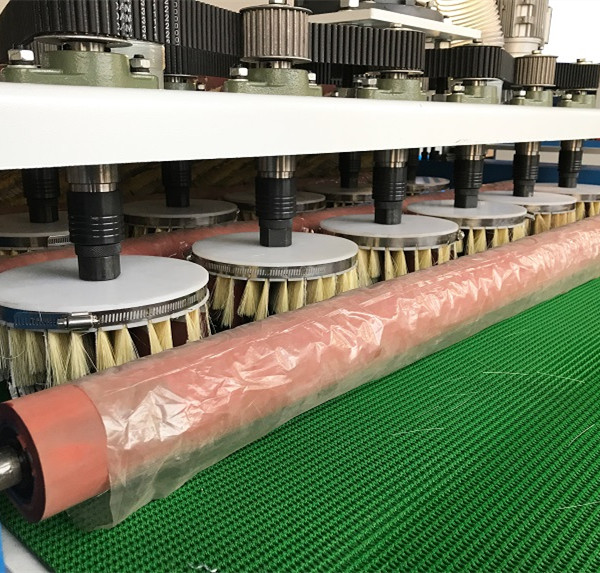

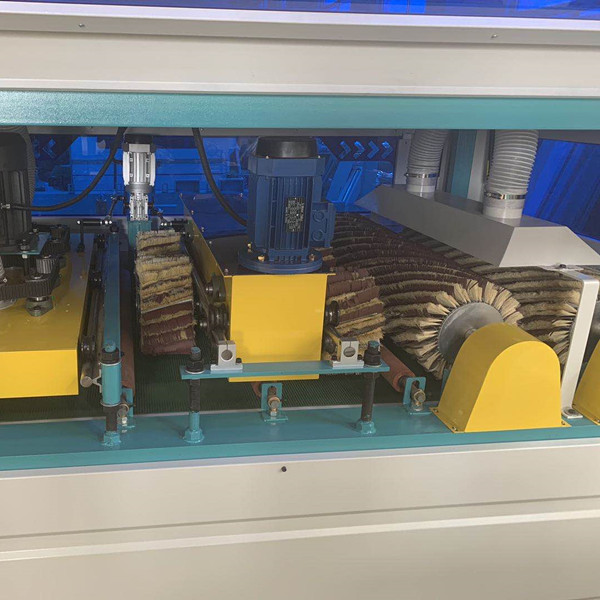

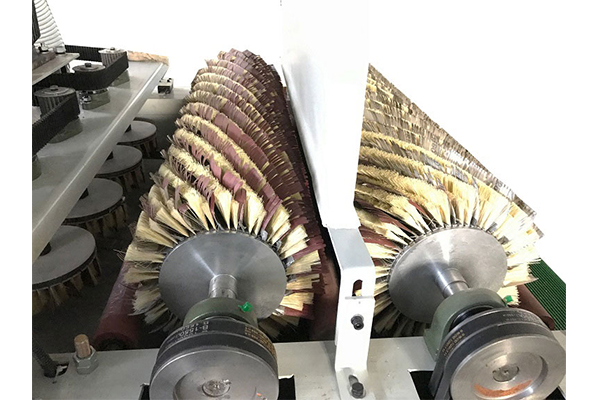

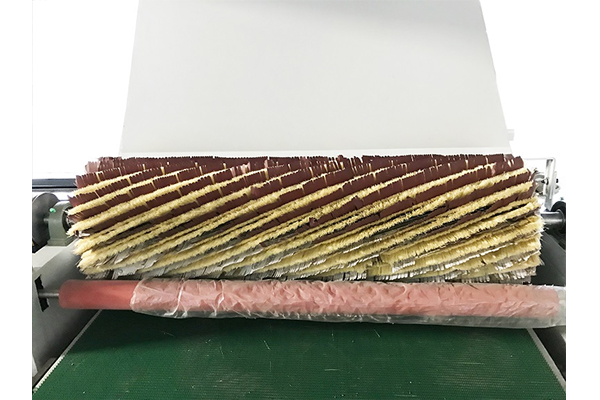

The Brush Sander Machine is composed of a sisal grinding wheel and a grinding wheel, one roller, one machine with two rollers, two-way forward and reverse grinding. It adopts multi-gradient grinding wheel tooth profile, combined with electric lifting to control the height of the roller group, for effective grinding of sheet surface milling or engraving simple grooves, etc., easy to operate, the combination of the two can grind complex and special-shaped flat plates at one time, with better results.

Brush Sander is a commonly used processing equipment for woodworking. As the name suggests, the name sander refers to the sanding treatment of wood surfaces. However, the role of modern wide-band sanding machine is not only to sand the surface of wood, it has many functions.

1. Fixed thickness sanding to improve the thickness accuracy of the workpiece, such as the veneer base material, which is used when the fixed thickness sanding is required before the veneer.

2. Surface sanding refers to the process of improving the surface quality and removing a layer of sand evenly on the surface of the board to eliminate the knife marks left by the previous process and make the surface of the board beautiful and smooth.

Clean, also used for veneer, dyeing, printing, painting.

3. Sand wool refers to the sanding process to improve the roughness of the back of the decorative board in order to ensure the bonding strength between the veneer of the decorative board and the base material.

Performance introduction

1. The processing quality of Brush Sander Machine is higher. Improving the sanding accuracy of the sander will become the future development direction of the sander.

2. The special-shaped sanding machine saves energy and reduces consumption. Sander is a large energy-consuming equipment on the wood processing production line, and energy saving and consumption reduction are very important.

3. The shape sanding machine has a higher degree of automation. The sanding machine is still blank in the automatic adjustment of the sanding process, and the automatic adjustment will reduce the human factor

The impact on the quality of processed plates.

4. The Brush Sander Machine is developing in the direction of safety and dust-free. To protect the main key components of the equipment and the personal safety of the staff. Shape sanding machine

Dust devices and dust-free sanding machines will become the future development trend.

5. Higher man-machine performance. Exquisite appearance and comfortable operation are the areas that users are most concerned about.

Products Show

This Brush Sander Machine is suitable for the polishing of solid wood furniture, wooden doors, density boards, mahogany, carved plates, etc.

Optional rules 1000, 1300 (four-axis, six-axis, eight-axis)

Regardless of whether it is a regular surface or a special-shaped surface and curved surface, rough and fine polishing can be carried out, and the sanding and polishing effect of the wood surface is remarkable.