Featured

-

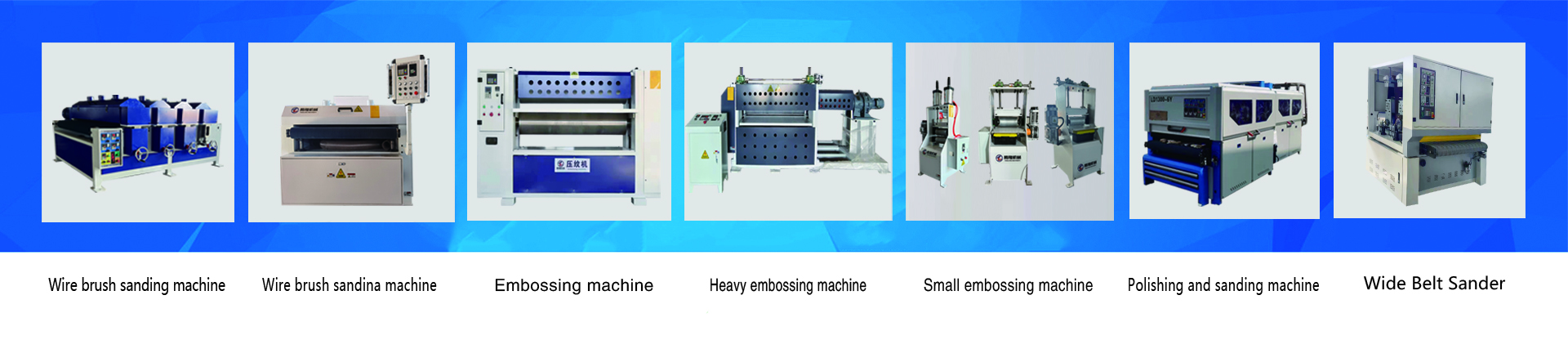

OEM Customized Big Wood Sander Machine - 1300-4 axis Wire Brush Sander – Tenglong Machinery

The working principle of the wire drawing machine: The wire drawing machine is composed of a wire drawing part and a winding part. The wire drawing part is composed of a wire drawing wheel, a mold holder, and a mold. After the wire passes through the mold, it is wound on the wire drawing wheel. During operation, the winding wheel runs to provide the traction tension of the wire. Under the action of the traction tension, the wire is wound through the drawing wheel to pass the wire through the ... -

Top Suppliers Double Head Wide Belt Sander - 1300-4 axis Wire Brush Sander – Tenglong Machinery

The working principle of the wire drawing machine: The wire drawing machine is composed of a wire drawing part and a winding part. The wire drawing part is composed of a wire drawing wheel, a mold holder, and a mold. After the wire passes through the mold, it is wound on the wire drawing wheel. During operation, the winding wheel runs to provide the traction tension of the wire. Under the action of the traction tension, the wire is wound through the drawing wheel to pass the wire through the ... -

Low price for Wood Planer Molder Machine – Aluminum Embossing Machine – Tenglong Machinery

Metal embossing machine is a kind of mechanical equipment used for embossing and forming thin metal plates such as aluminum plates, color steel plates, copper plates, and stainless steel plates. The metal embossing machine includes a frame, a guide roller, an embossing roller, a transmission device and an adjustment device. The guide roller, the embossing roller and the transmission device are all fixed on the frame, and there are two guide rollers. They are respectively located on bot... -

Excellent quality Mini Edge Banding Machine - Automatic Edge Banding Machine – Tenglong Machinery

1. Feeding group: Put the card into the cassette, and pull the card down to the transport arm by the pulling cylinder using the vacuum suction cup. 2. Material rack group: Put the chip hot melt tape into the material rack correspondingly, and then introduce the chip hot melt adhesive through the guide wheel into the rubber punching paper mold, pre-soldering group, punching chip group, etc., Lead the belt into the corresponding position and put it away. 3. Pre-welding group: heating element he... -

Manufacturing Companies for Sanding Machine For Plastic - Brush Sander Machine for Wood – Tenglong Machinery

The special-shaped sanding machine is composed of a sisal grinding wheel and a grinding wheel, one roller, one machine with two rollers, two-way forward and reverse grinding. It adopts multi-gradient grinding wheel tooth profile, combined with electric lifting to control the height of the roller group, for effective grinding of sheet surface milling or engraving simple grooves, etc., easy to operate, the combination of the two can grind complex and special-shaped flat plates at one time, with... -

Leading Manufacturer for Roller Embossing Machine - 300mm WPC Embossing Machine – Tenglong Machinery

Basic Info. Platen Surface Pressure Medium Pressure Work Mode Continuous Controlling Mode CNC Automatic Grade Automatic Certification ISO Work Forms Continuous Pressing Shape Continuous Trademark Tenglong Transport Package Customization Specification 2300*1300*1600mm Origin China HS Code 8477800000 Xuzhou tenglong machinery company’s own development of various tree patterns, patterns using material from imported 5-axis CNC laser engraving machine processing prod... -

Factory Price Sanding Machine For Plywood - Brush Sander Machine for MDF – Tenglong Machinery

The special-shaped sanding machine is composed of a sisal grinding wheel and a grinding wheel, one roller, one machine with two rollers, two-way forward and reverse grinding. It adopts multi-gradient grinding wheel tooth profile, combined with electric lifting to control the height of the roller group, for effective grinding of sheet surface milling or engraving simple grooves, etc., easy to operate, the combination of the two can grind complex and special-shaped flat plates at one time, with... -

Factory wholesale Wood Sanding Machine Price - Brush Sander Machine,Used for polishing solid wood furniture – Tenglong Machinery

The special-shaped sanding machine is composed of a sisal grinding wheel and a grinding wheel, one roller, one machine with two rollers, two-way forward and reverse grinding. It adopts multi-gradient grinding wheel tooth profile, combined with electric lifting to control the height of the roller group, for effective grinding of sheet surface milling or engraving simple grooves, etc., easy to operate, the combination of the two can grind complex and special-shaped flat plates at one time, with... -

factory low price Wood Embossing Machine For Sale - 300mm Wood Embossing Machine – Tenglong Machinery

Basic Info. Platen Surface Pressure Medium Pressure Work Mode Continuous Controlling Mode CNC Automatic Grade Automatic Certification ISO Work Forms Continuous Pressing Shape Continuous Trademark Tenglong Transport Package Customization Specification 2300*1300*1600mm Origin China HS Code 8477800000 Xuzhou tenglong machinery company’s own development of various tree patterns, patterns using material from imported 5-axis CNC laser engraving machine processing prod... -

Manufacturer of Sliding Table For Saw - Horizontal band saw machine – Tenglong Machinery

Horizontal woodworking band saw machine is composed of saw frame, parallelogram adjustment device or four screw adjustment device, grinding saw machine, rail and lifting bracket. A tool for removing the veneer from the bottom of the log. When the machine is working, the wood is fixed and the track is fixed on the wood. The sawing machine is installed on the track, and the thickness of the processed wood is adjusted through the parallelogram adjusting device, so that the sawing machine cuts al... -

Chinese wholesale Wood Pattern Embossing Machine - Double head wood embossing machine – Tenglong Machinery

Xuzhou Tenglong Machinery Co., Ltd. focuses on the development and production of solid wood equipment, panel equipment, aluminum equipment and other furniture processing equipment. The company has strong R&D and manufacturing capabilities, professional technical guidance, and the purpose of “quality first, customer first, and service improvement” as its purpose. Double-head branding machine is suitable for solid wood door cabinet embossing, hot stamping, picture frame e... -

Special Design for Woodworking Edge Bander Machine - Automatic Edge Banding Machine – Tenglong Machinery

1. Feeding group: Put the card into the cassette, and pull the card down to the transport arm by the pulling cylinder using the vacuum suction cup. 2. Material rack group: Put the chip hot melt tape into the material rack correspondingly, and then introduce the chip hot melt adhesive through the guide wheel into the rubber punching paper mold, pre-soldering group, punching chip group, etc., Lead the belt into the corresponding position and put it away. 3. Pre-welding group: heating element he...