MDF Roller Embossing Machine

Basic Info.

| Platen Surface Pressure | Medium Pressure | Work Mode | Continuous |

| Controlling Mode | CNC | Automatic Grade | Automatic |

| Certification | ISO | Work Forms | Continuous |

| Pressing Shape | Continuous | Trademark | Tenglong |

| Transport Package | Customization | Specification | 2300*1300*1600mm |

| Origin | China | HS Code | 8477800000 |

Product Description

Xuzhou tenglong machinery company's own development of various tree patterns, patterns using material from imported 5-axis CNC laser engraving machine processing production.

Pattern according to sample, automatic lifting equipment, embossing depth uniform, embossing depth digital display adjustment, transmission mode for frequency conversion control! All low-voltage electrical appliances adopt Chint brand, heating power: 6kw.9kw.12kw, opening and closing distance of two rollers: 0-120mm. Wiring adopts national standard three-phase five wire system, with high protection safety level.

The surface of the roller is engraved by computer, and the surface is plated with hard chromium. The rotary conductive ring is used for heating.

Our company has developed a variety of embossing machines according to customer requirements, including 650, 1000 and 1300, and can also be customized according to customer requirements.

Product Parameters

Technical parameters of 1300 embossing machine:

1.High quality 45 steel is selected as the pattern roller

2.Pattern roller independent electric heating system

3.The diameter of patterned roller is 320mm, and the surface is electroplated

4.Self aligning roller bearing with high temperature lubricating grease

5.Wall plate steel structure, heat treatment and stress relief

6.Maximum embossing width 1220mm

7.Embossing frequency control, 1-15m / min

8.Processing thickness: 1-150 mm

9.Pattern depth: 0.1-1.2mm

10.Overall dimension of the machine: L * w * H = 2200 * 1200 * 1500 mm

Detailed Photos

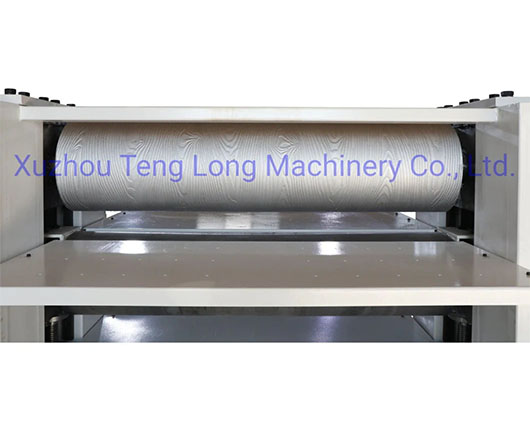

ROLLER:

Can change double pattern or single pattern

Hundred nature woodgrain patterns alternative

Patterns can be customized

Roller surface is plated with hard chromium

The roller material is high quality NO.45 steel

Embossing depth can be adjusted from 0.1~1.2mm

Inter:self aligning roller bearing with high temperature lubricating grease

BUTTON CONTROL:

☆Woodworking thickness gauge

☆Frequency changer panel

☆Temperature indicator

☆Jintian brand can changed to Schneider